1968 Corvette: Service Bulletin: Windshield Wiper System - Operation and Diagnosis

Estimated Reading Time: 7 Minutes Model Year: 1968

Subject: 1968 Corvette Windshield Wiper System - Operation and Diagnosis

Source: Chevrolet Dealer Technical Service Bulletin

Number: 68-T-34

Date: Mar. 11, 1968

To: All Chevrolet Dealers

This bulletin is being published as an aid to understand and to easily diagnose 1968 Corvette windshield wiper system.

The system is a double articulating, overlapping type in which the blades park under a concealing vacuum operated lid. The wiper motor is electric and the lid is vacuum operated. The movements of each are programmed to prevent damage to system components.

Vacuum components for wiper door operation are as follows:

- The vacuum reserve tank and check valve, to store vacuum for door operation, is located under rear of left fender near cowl.

- The vacuum relay valve, to route vacuum to proper side of door actuator for opening or closing cycle, is located under rear of right front fender. This valve is operated by vacuum on a spring loaded diaphragm.

- A vacuum control valve solenoid, used to activate or deactivate the vacuum relay when the wiper switch is turned on or off, is mounted on the tachometer housing under the dash.

- A manual valve in series with the solenoid is used to open the door for service procedure. This switch should also be used to keep the door open when frequent but intermittent wiper use is desirable.

- Reserve tank, check valve and hoses, constitute the remainder of the vacuum system components. The tank and check valve are common with the headlamp vacuum system.

Electrical components of the wiper system are:

- Wiper motor - with an integral relay. The motor has separate leads to external ground for completing the armature and field circuits.

- Wiper switch on dash is sued to provide the wiper system with off, low and high speed conditions. This switch is a ground switch.

- A limit switch, operated by the wiper door as it reaches open position is mounted on the engine side of the cowl near the wiper motor. This switch is used to interrupt the motor armature ground circuit until the wiper door is fully open. When limit switch completed this circuit, the motor will operate.

- A rotary Service switch mounted under the dash in steering column area is used to stop the wiper blades in a serviceable position on the windshield. This switch should never be left open for more than short service periods because it does not allow the motor to come to a park position. This can result in a dead battery even with the ignition switch turned off.

- An external relay completed the motor field circuit to ground at the wiper switch or through a ground wire. This relay is used to return the wipers to slow speed and allow the blades to park for door closing if the ignition is turned of while the wiper switch is in high speed position.

This relay is mounted under the front of the floor console and is accessible after removing the slide out trim at the right front side. - Vacuum motor solenoid is an electrically controlled vacuum switch as outlined under vacuum components.

- Windshield wiper fuse in fuse panel -- controls the feed circuit for the external relay, the motor relay and the washer solenoid. The yellow wires are protected by this fuse and are hot any time the ignition switch is on.

- Fuse link at horn relay protects feed (red) wire to wiper. This lead is always hot.

- Refer to 1968 New Product Training Program Booklet, Page 58-60 or to the September-October Service News for detailed electrical theory of operation.

Wiper Motor and Switch Operation Check -

- Open wiper doors using the vacuum over-ride switch or manually at the actuator.

- Install a test prod in wiper terminal #6 and connect a jumper wire from test prod to ground. (This bypasses limit switch and service switch).

- Disconnect harness connector from terminals #1, #2, and #3.

- Connect a jumper lead from junction block at horn relay to terminal #2 at wiper motor. If suspicious of ground lead (-) to wiper, connect a separate jumper from wiper motor to engine block.

- "LO" speed operation - connect wiper terminal #1 and #3 to ground.

- "HI" speed operation - Leave wiper terminal #1 connected to ground but disconnect #3 from ground.

- Shut off and/or park - Reconnect terminal #3 to ground and disconnect terminal #1 from ground. Wiper motor should run until blades reach full park position.

- If wiper motor fails to operate, wiper motor is malfunctioning.

- Remove test prod ground (step 2) and repeat steps 5 and 6 above to check continuity through limit and service switches.

- Using jumper wire, connect it individually across the terminals of each suspected switch until defective switch is located.

Note:An interim change will incorporate a telltale light into instrument cluster below the door ajar light which will glow when the service switch is left open or if the wiper door doesn’t operate the limit switch fully. There is a constant drain on the battery with the service switch in the "ON" position (even with ignition "OFF").

- Check dash switch or external relay. (Refer to figure 4)

- To by-pass external relay contacts, disconnect wiring from relay and connect a jumper wire between terminals as shown.

- Reconnect wiring to wiper motor and operate wiper with dash switch thru "LO", "HI" speeds and park. If wiper operates correctly, external relay is defective.

- Wiper does not operate correctly (any malfunction), dash switch and/or wiring to switch is defective.

Wiper Door Locks - Not Full Open Positions

- Check to see that door actuator rod is adjusted to allow full open position.

- Check the Windshield Wiper access Door Linkage Bolt for binding action with bushing under the head of the bolt.

- Back-off on bolt torque

- If binding sill pronounced, remove bolt from assembly. Shave away busing flash and reassemble bolt after lubricating the bolt-bushing mating surface with waterproof lubricant.

- If binding is still evident, replace bolt with new bolt #3945216 inserting a spring washer #3940537 (this spring to be coded in warehouse 4/1/68) behind the bolt head.

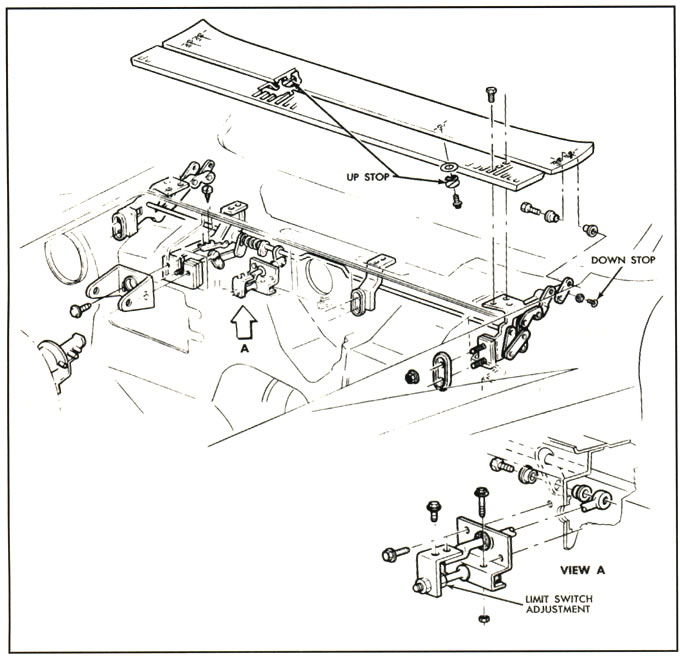

Door Closes Too Fast - (Up Stops - Fig 5)

Check door height above grille in fully open position. If the dimension from underside of door-top of grille (center of door) is less than 3/16 inch, and washers behind door bumper assemblies to shim to required height.

Door Hits Windshield When Closed - (Down Stops - Fig. 5)

Adjust stops to obtain 1/16 inch clearance between door and windshield when door is in closed position.

Wiper Arm Adjustment (Early Units)

When over-travel of the windshield wipers occurs and they hit the pillar and/or they hit each other at center of wipe pattern on a wet windshield and the side arm adjusting screws will not correct, initiate the following:

- Remove plenum vent grille as outlined in Chassis Shop Manual (Page 12-54).

- Adjust windshield wiper transmission rods inboard at wiper motor adapter adjustment provisions and set R.H. & LH arm adjusting screws to center position.

- With wiper arms in "park" position remove arms from serrated transmission heads.

- Grind existing keys off L.H. and R.H. serrated transmission heads.

- Install L.H. wiper arm 1.5" below park stop, then lift wiper blade over park stop to normal park position.

- Install R.H. wiper blade 1.0" above L.H. blade in its park position.

- Do not use any blades other than Trico or equivalent which is regular service release.

- Connect washer hoses to nozzles and install plenum vent grille.

- Now test windshield wiper operation on a wet windshield. If any fine adjustment is still necessary use adjusting screws on side of arms.

- If problem cannot be corrected by adjustment, remove (right hand) transmission assembly and wiper arm rod assembly and replace with new transmission assembly (#4919036) and rod assembly (#3942736).

- Adjust as outlined above omitting steps 3 and 4.

Chevrolet Motor Division

General Motors Corporation

c: Dealer List

Chevrolet List

- Source: Vette Vues - December 2001