Something Wicked This Way Comes: the 2014 C7 Corvette Stingray is Unveiled: Page 10 of 11

The Corvette Action Center takes an up close and personal look at the C7 Corvette and interviews the key players behind it.

by Robert Loszewski

© February 2013

No use without permission, All Rights Reserved

Corvette Action Center: When dealing with suppliers, do you sometimes run into an issue where a supplier will come back to you and say "we can't produce this particular part at the quality you want for the price that you want"?

Alicia Boler-Davis: Absolutely. We have our suppliers, sometimes come to us and say, "we have a recommendation on how we can improve the overall part and how it can be produced more efficiently which could help us both save money". They're expected to have the same continuous improvement process that we talked about in the plant.

Sometimes we'll make changes on the part. Sometimes we'll change a part from when we originally sourced it, and then the supplier has the opportunity to come back and tell us what that change will cost. Sometimes [it cost] more that we sourced, then we'll negotiate what it should be.

When a supplier is sourced a certain level of work, they are responsible for doing due diligence; understanding what it's going to take in order to produce the part at the quality levels consistently. When they give us a piece-cost for that, we expect that to be the cost. Now if we make changes, or they want to make some improvements, then we work through that.

Corvette Action Center: Does the manufacturer have its own quality checks on the parts that they produce and does the Bowling Green Assembly Plant have their own quality checks on parts as they go on the car down the line?

Alicia Boler-Davis: The answer to your first question is yes. Every supplier is expected to have a robust quality system and part of that is a process control plan to control the process. The other is sampling. They are responsible to do sampling of key components. So key characteristics of the part — they have to check it and send that data to us. That's how we know the process is in control. Depending on the part, it may be a certain number per hour, or a certain number per shift.

Now in the Assembly Plant, we're not in the habit of inspecting parts. We expect that the parts are going to come in and that they're going to meet the requirement. We do inspect the product at different points in the build, and we inspect it to a certain standard. We do drive the vehicles and we evaluate them.

If we've had an issue with a certain part, we do inspect that. We get a breakpoint from the supplier, and then we do random sampling until we're confident that the supplier is back in control and we're not putting our customers at risk. So, there are people in the plant that will inspect the parts, but it's usually because we've had an issue at either that plant, or another location has had an issue and we want to make sure we're protected. But random inspection of parts doesn't usually happen.

Dan Adovasio: As far as the enthusiasts or owners of the car go, when they run into a problem with their car, usually the first step they do is take it to a dealer. If they have a problem with the dealer, what's the next step they should do?

Alicia Boler-Davis: The first thing they should do is go to the dealer. Preferably, the dealer they purchased the vehicle from because we want the dealer to have a relationship with the customer. If for some reason, the dealer cannot resolve the issue, then we have a 1-800 number that the customers can call and we have agents that are available to assist the customer in getting the issue resolved. They can also go on Chevrolet.com and there's a button they can click where they can engage an agent that way.

Driving and Performance

So, with all of this new technology going into Chevrolet's latest and greatest Corvette, how is the ride, handling and performance you ask? Good question! It will probably be another 3-6 months before the media is invited to test drive the varioius C7 models in Michigan, however we did ask a couple people from GM what they thought of their driving experience.

Alicia Boler-Davis: The engine and its horsepower is key and the ride and handling is great. I had a chance to drive one of these vehicles a couple months ago and it was pretty amazing. After riding in it, driving it and seeing it again, I think I'm going to have to acquiesce and get one. It's a great vehicle.

We then asked Mark Reuss, President, GM North America if he had a chance to drive the C7:

Corvette Action Center: Have you driven the C7 and what were your impressions?

Mark Reuss: Yes I have. [big smile] We drove the first mules of the car that were built off of a C6 when we were configuring the chassis from a mule standpoint, and we knew we hit a home run. Two weeks ago we went down to Bowling Green and drove the first five cars that came off the line, and it was pouring rain unfortunately. The next session will be in April somewhere in Europe so we're going to put it through the calibration piece of it there.

I got to drive all five modes in pouring rain, and it is really good. We drove it against the dual-clutch 911 [Porsche], the C6 Z06, and it's a great ride. I can tell you that the car is *pretty* spectacular!

Closing Thoughts

Whether you love it or hate it, there's no disputing that the 2014 C7 Corvette Stingray is bold, exciting, and the shot of adrenaline that Corvette really needs to stay alive.

Over the last three generations of the marque, Corvette design has remained very conservative. We haven't seen the drastic changes reminiscent of going from the C1 to C2, or C2 to C3 generations. The last biggest change we saw was going from the 1982 to 1984 Corvettes. Since then, the biggest changes we've seen have been under the skin in terms of engineering. The overall design really didn't change that much, and in my opinion, I think it was probably because Corvete designers wanted to remain conservative as to not lose the majority of enthusiasts they've gained over the years.

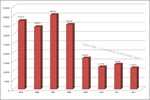

However, when you own a company, and all of a sudden you start to see a pretty dramatic decrease in the amount of revenue your product is bringing in - it doesn't take a rocket scientist to realize - something has to change. You either kill the product and offer something different, or you take that product, re-work it and make it a point to wow the masses and attract new buyers. This is exactly what GM needed to do with the Corvette.

In looking at C6 production numbers from 2005 - 2012 - you can easily see - something had to change:

| Model Year | Coupe | Convertible | Z06 | ZR1 | Grand Sport Coupe | Grand Sport Convertible | Total |

|---|---|---|---|---|---|---|---|

| 2005 | 26728 | 10644 | 37372 | ||||

| 2006 | 16598 | 11151 | 6272 | 34021 | |||

| 2007 | 21484 | 10918 | 8159 | 40561 | |||

| 2008 | 20030 | 7549 | 7731 | 35310 | |||

| 2009 | 8737 | 3343 | 3461 | 1415 | 16956 | ||

| 2010 | 3054 | 1003 | 518 | 1577 | 3707 | 2335 | 12194 |

| 2011 | 3112 | 780 | 906 | 806 | 5212 | 2782 | 13598 |

| 2012 | 2820 | 621 | 478 | 404 | 5056 | 2268 | 11647 |