2014 C7 Corvette LT1 Fact Sheet #4 - Corvette, the Small Block V-8 and LT1

Source: GM Media

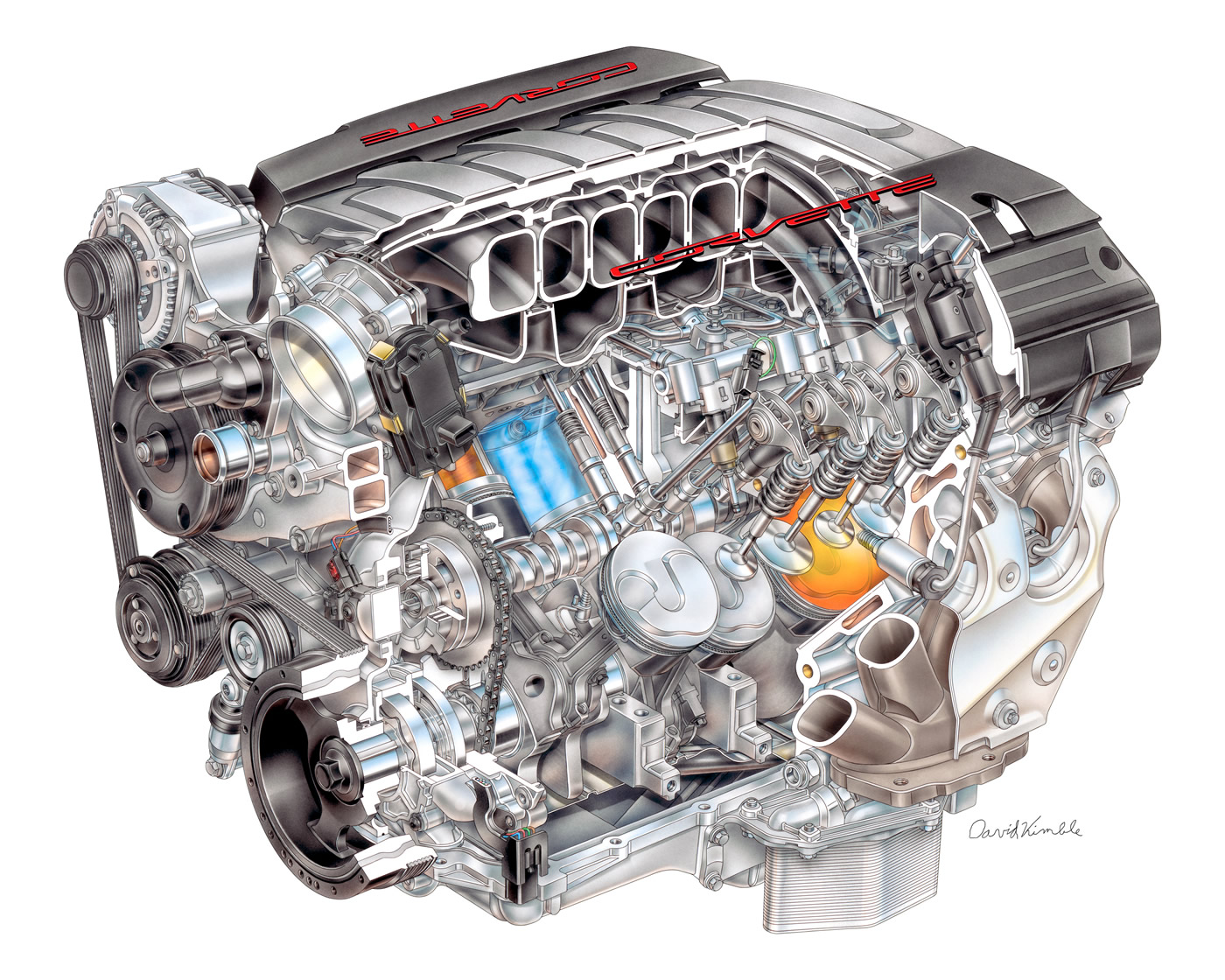

When the next Corvette hits the street and racetrack, it will do so with an all-new, Gen 5 Small Block V-8 engine. Named LT1, it will be the most powerful and efficient standard engine ever in the car's six-decade history, thanks to a trio of Next-Gen technologies — the first Corvette applications of direct injection, Active Fuel Management and continuously variable valve timing — for greater performance and efficiency.

The Corvette wasn't born with a V-8 between its front wheels. It arrived in the fledging sports car's third model year, 1955, where it was an option selected by 90 percent of customers. That first 4.3L (265 cu. in.) engine produced 195 horsepower (145 kW) with a four-barrel carburetor. The new Gen 5 LT1 — the third Small Block to carry the moniker — displaces 6.2L (376 cu.-in.) and delivers an estimated 450 horsepower (335 kW).

The Small Block V-8 engine was physically smaller, 50 pounds lighter and more powerful than the “Blue Flame” inline-six engine it replaced in the 1955 Corvette. Its 4.4-inch bore centers — the distance from the center of one cylinder to the next — would come to symbolize the compact, balanced performance of the engine's architecture. Every generation of the Small Block — including the forthcoming Gen 5 — features 4.4-inch bore centers.

After only two years on the market, the Small Block began a steady march upward in displacement, power and technological advancement. In 1957, a version equipped with mechanical fuel injection was introduced, dubbed Ramjet. The only other high-volume manufacturer to offer fuel injection at the time was Mercedes-Benz.

Mechanical fuel injection was discontinued in the mid-Sixties, but the Small Block introduced electronically controlled fuel injection in the 1980s on the Corvette and established a benchmark with the 1985 launch of Tuned Port Injection on the C4 Corvette generation. This electronically controlled port fuel injection system was advanced in its day and its basic design is still used on most passenger cars and light-duty trucks more than a quarter-century later.

The introduction of the Gen 3 Small Block with the 1997 launch of the C5 Corvette ushered in a new era of technologically advanced performance. It was a clean-sheet redesign of the architecture — retaining, of course, the 4.4-inch bore centers and cam-in-block foundation — with features including an aluminum, long-skirt cylinder block with six main cap fasteners, high-flow cylinder heads that improved high-rpm horsepower and a lightweight composite intake manifold.

As the C6 Corvette enters its final year, it sends off the Gen 4 Small Block with a couple of notable distinctions: The 7.0L LS7 engine that powers the Corvette Z06 is the largest-displacement production Small Block ever, while the 638-horserpower 6.2L supercharged LS9 engine in the Corvette ZR1 is the most powerful production Small Block ever, helping power the car to a 205-mph top speed.

LT1 legacy

The first LT-1 (with a hyphen) engine was introduced in the Corvette in 1970 as an option. It was a raucous, racing-inspired engine with solid valve lifters, a high-lift camshaft and high-winding personality that redefined Small Block performance. Displacing 350 cubic inches (5.7L), with a compression ratio of 11:1, it was rated at 370 horsepower at 6,000 rpm and 380 lb.-ft. of torque at 4,000 rpm. It was enough to push the Corvette from 0 to 60 mph in less than six seconds.

Indeed, the LT-1 was a true high-performance powerhouse, featuring many heavy-duty components not found on the Corvette's standard 350 engine, including a stronger cylinder block with four-bolt main caps, forged aluminum pistons, a high-rise aluminum intake manifold, a baffled oil pan for reduced windage, a transistorized ignition system and high-volume oil and fuel pumps.

Only 1,287 Corvette's left the factory in 1970 with the LT-1 engine. It remained in production for another couple of years, but lower compression ratios and other regulations-conforming changes resulted in lower horsepower.

The LT1 (no hyphen) returned to the Corvette in 1992, launching the five-year lifespan of the Gen 2 Small Block. It built on the successful design of the L98-code Gen I Small Block that debuted in the 1985, featuring the port fuel injection design that most automotive engines still use today. Like the original LT-1, the Gen 2 version displaced 350 cubic inches and featured a four-bolt-main block.

The Gen 2 LT1's most significant update over the Gen I Small Block was a reverse-flow cooling system, which cooled the cylinder heads first to achieve lower cylinder temperatures. That allowed a higher, 10.4:1 compression ratio that helped achieve greater power: 300 horsepower at 5,000 rpm and 330 lb.-ft. of torque at 4,000 rpm. It helped the Corvette achieve 0-60 acceleration comparable to the 1970 model, while also helping propel the 1992 model to a top speed of more than 160 mph.

To mark the final year for the C4 Corvette generation and the final year for the Gen 2 Small Block, a pair of special-edition models was offered in 1996 with a higher-power version of the engine, dubbed LT4. It was rated at 330 horsepower and is easily identified by its red cast-aluminum intake manifold.

After an 18-year hiatus, the LT1 returns to the Corvette for 2014, matching an all-new car with an all-new Gen 5 engine — one of the most technically advanced engines in the world and the most significant redesign of the Small Block ever. It will have the highest base horsepower and torque, as well as the greatest efficiency, of any Corvette in its 60-year history.

With preliminary output of 450 horsepower (335 kW), the new LT1 builds on a heritage of high-winding, power-dense Small Blocks that have become high-performance legends.

LT1 engines compared

| 1970 LT-1 (Gen 1) | 1992 LT1 (Gen 2) | 2014 LT1 (Gen 5) | |

| Displacement | 350 (5.7L) | 350 (5.7L) | 376 (6.2L) |

| Bore x Stroke (inches) | 4.00 x 3.48 | 4.00 x 3.48 | 4.06 x 3.62 |

| Cylinder block | cast iron | cast iron | cast aluminum |

| Main bearing cap fasteners | four | four | six |

| Cylinder heads | cast iron | cast aluminum | cast aluminum |

| Valve sizes (intake / exhaust) | 2.02 / 1.60 inches | 1.94 / 1.50 inches | 2.13 / 1.59 inches |

| Compression ratio | 11.0:1 | 10.4:1 | 11.5:1 |

| Camshaft type | solid lifter | hydraulic | hydraulic |

| Fuel delivery | four-barrel carburetor | port fuel injection | direct injection |

| Ignition | transistorized with cam-driven distributor | “Optispark” optically triggered distributor | individual coil-on-plug |

| Horsepower | 370 @ 6,000 rpm | 300 @ 5,000 rpm | 450 (estimated) |

# # #