GM TechLink, January 2003

A tire pressure monitor (TPM) system is used on Cadillac DeVille, Seville and Chevrolet Corvette. This system was discussed in the November 2000 TechLink. This is a brief review, because there is some new service information available.

Components

There is a separate sensor/transmitter in each wheel. The TPM system shares the receiver with the keyless entry system. Data from the receiver is displayed on the instrument panel, using the driver information center (DIC).

Sensors

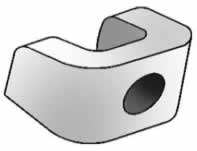

The sensor, with built-in valve stem, is inserted from the inside of the wheel, through a hole in the rim. It is retained by a nut (4 N.m, 35 lb. in.) and is sealed by a grommet. A lithium battery with a design life of 10 years powers the sensor.

Each sensor is coded differently. This permits the receiver to determine exactly which tire is over or under-inflated.

Operation

The sensors operate only above 20 mph (32 kph) and transmit once per hour when parked, to preserve battery power.

If the pressure in a tire rises or falls outside the calibration limits, the condition is displayed by the DIC. The low limit is 24 psi (168 kPa) and the upper limit is 39 psi (272 kPa).

Service

The sensors are lightweight, only about an ounce (28 g), and this small weight is easily accounted for during normal tire balancing.

The sensors are mounted within the well of the rim. It’s important to be careful when using a tire-mounting machine. The sensor could be damaged in two ways: either by (1) direct contact with the machinery or (2) by the bead of the tire as it is forced over the rim.

Use care when using tire machine.

Consult tire changer manufacturer’s support material for proper mounting procedures.

Sensor ruined by tire mounting equipment

The valve stem cap is made of aluminum and the valve core is nickel-plated to resist corrosion. The end of the stem serves as the sensor’s antenna.

TIP: Do not replace either the cap or the valve with standard parts. This will interfere with the sensor’s ability to transmit.

TIP: The TPM sensor is more precise than consumer-grade tire pressure gauges. It may be necessary to explain this if the customer routinely mis-inflates tires using a gas station gauge.

Receiver Programming

The receiver is programmed at the factory to recognize which sensor is at each wheel location. If tires are rotated or a sensor is replaced, the receiver must be reprogrammed, following SI procedures.

If the receiver is not reprogrammed, the system will continue to report the correct pressures, but will assign them to the wrong locations on the vehicle.

TIP: There are two reprogramming methods. You must use the J-41760 magnet when a new sensor is installed. During tire rotation, you can use either the magnet or your Tech 2.

J-41760 Magnet

Magnet Method

You will have only one minute between horn chirps, and five minutes overall, to complete the procedure once you start.

With ignition on, engine not running, press both lock and unlock buttons on the key fob. A horn chirp within 10 seconds indicates that the receiver is in programming mode.

At each wheel, hold the J-41760 magnet over the valve stem until the horn chirps, to force the sensor to transmit its code. You must follow this order: LF, RF, RR and LR. The horn chirps twice to indicate completion.

Scroll through the DIC readout to verify all four pressures are displayed.

Tech 2 Method

With the TPM Reprogramming procedure on your Tech 2, you can command each sensor to its new location. As long as no new sensors are being installed, the magnet is not needed.

Scroll through the DIC readout to verify all four pressures are displayed.

Instrument Cluster Module Programming

On the Seville and DeVille models, if you disconnect or replace the IP cluster, the IP module must also be programmed to enable the TPM option. If this is not done, the DIC will not be able to display information from TPM receiver.

Follow this path on your Tech 2.

Additional Tips

Because the TPM system shares its receiver with the remote locking system, the TPM function is turned off in vehicles that are built without the TPM system. It is possible to add TPM to one of these vehicles by adding the appropriate wheels and sensors. In this case, the TPM option must be enabled in the receiver.

TIP: If the horn does not chirp at the beginning of the reprogramming procedure (Magnet Method, above), this is a good indication that the TPM option has not been enabled.

Follow this path on your Tech 2:

The system is now enabled.

If the car’s battery or the receiver is disconnected, or the voltage drops below a certain value, the receiver will lose all sensor Ids. It then sets all four DTCs. In this case, it must be reprogrammed using the magnet.

Sensor Batteries

On the Cadillac system only, the status of the sensor batteries is presented in the TPM data list. The sensors are built to continue to operate for three months after the batteries reach low status. When the battery in a sensor runs down, it is necessary to replace the sensor. Batteries are not serviceable.

Thanks to Russ Dobson, Scott Bower, John Spidle and Chuck Kennedy.

Article ID: 375

Created: July 21, 2014

Last Updated: July 21, 2014

Online URL: https://www.corvetteactioncenter.com/tech/knowledgebase/article/1997-2004-corvette-gm-techlink-tire-pressure-monitoring-system-information-375.html