2009 Corvette ZR1: Ruthless Pursuit of Power: Supercharged Edition - Page 6 of 7

|

|

Page 6 of 7

© 2008 by Hib Halverson

No use without permission, All Rights Reserved

![]() Discuss this article

Discuss this article

Cylinder Heads—Hot-Boxed and Rotacast

Early interations of the LS9 cylinder head were called the "Corvette Supersport Head" an acknowlegement that, at one time, what ended up the "ZR1" was originally going to be called the "Corvette SS". The LS9 cylinder head is based on the LS3/L92 unit, also discussed in our LS3 story, but has several differences: 1) its material is A356, a more robust variety of aluminum than the 356 used in the LS3 casting. The heat treat specification for both is T6.

2) It is cast with the "Rotacast™" method (sometimes known as "roll-over" casting) rather than the semi-permanent mold process used with other heads. Rotacasting begins with the molds inverted. As the molds slowly rotate 180°, molten aluminum is poured in. Solidification begins before the mold stops rotating but isn't completed until after it stops. This process causes "directional solidification" which makes a stronger, less porous casting.

Because Rotacasting increases the stress on the LS9 water jacket core, it is made with the "hot-box" process. Water jacket cores for all Small-Block heads except those destined for supercharged engines are made with the "cold-box" process which uses "TEA" gas at room temperature to cure the resin in the core sand. SC heads are made with cores which are heat-cured. The "hot-box" process results in cores with higher tensile strength to better resist deflection during the rollover casting process.

3) Head structure was modified for compatibility with Rotacasting and reinforced with posts and ribs inside the cooling jacket, above the combustion chamber, to provide reliability/durability at the combustion pressures a supercharged engine sustains. The structure enhancement was difficult to execute in a manner that did not restrict coolant flow enough to degrade engine cooling.

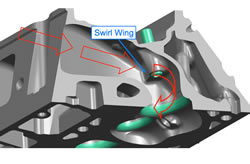

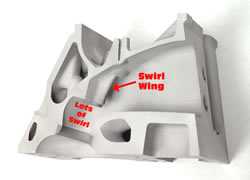

4) A small deflector-GM calls it a "swirl wing" was cast into the roof of each intake port, to the left of intake valve guide, where the roof begins to curve across the guide and down to the valve seat. "Swirl" is a high-velocity, cyclonic airflow motion which breaks-up the fuel droplets making the air/fuel mix more homogenous and promoting better combustion dynamics. With the LS3, L92 and LS9 head, swirl is counter-clockwise and takes place mostly in the section of the port engineers call the "bore" and enthusiast community calls the "valve throat" or the "pocket", with little or no swirl motion at the valve seat.

In the supercharged head, this deflector forces airflow to the bore-wall side of the port to enhance the swirl motion, once it gets into the bore. The swirl wing's effect increases combustion efficiency, reduces exhaust emissions and improves idle stability. While in a supercharged engine, these deflectors present virtually no restriction to air flow; in a normally aspirated application, they cause measurable power loss, so they are not present in the LS3/L92 casting.

It's been reported that this deflector exists to improve idle stability of the Cadillac offshoot of this engine, the LSA, however, while the swirl wing does, indeed, improve idle stability; it doesn't exist solely for that purpose. The main reasons for it are better combustion and lower emissions, across the board, on all the SC Small-Blocks and regardless of engine speed. It's, also, been reported that this air flow device was simply a bump in the port roof but, as you can see from our photos of the LS9 intake port, it truly is a deflector or "wing" and not a bump.

5) The LS9 intake valve seat is made of the same PMF28 material used by the LS7 but is the smaller, LS9 diameter. PFM28 is compatible with a titanium valve, whereas the Brico 3010 intake seats used in heads with steel intake valves are not. The LS3's Brico 3220, exhaust seat carries over. Also carrying to LS9 from the LS3 head is valve seats machined with three angles.

With any supercharged engine, head gasket sealing is a critical issue. The LS9 gasket is an example of GM Powertrain advancing the state-of-the-art in sealing technology. It uses the multi-layer steel design (MLS) which, by now, is becoming commonplace with Gen 4 engines, but it's an unprecedented, seven-layer design with four "active" compressible layers. Without four active layer head gaskets, M12 head bolts, and a stiffer head structure, all to reduce head "lift-off", the Small-Block Team would never have been able to reach the power output of the production LS9.

Cam and Valvetrain

As are all production Gen 3/4 camshafts, the cam in the LS9 is a rifle-drilled, steel billet and uses roller hydraulic lifters. Like the LS6 and 7, it uses a smaller base circle radius than other Gen 3/4 engines, in this case 18.9mm. Valve stem length is lengthened to match the smaller base circle radius.

The LS9 camshaft's intake and exhaust profiles are the same as that of the LS7. More than a decade of experience with high-performance versions of the Gen 3/4 engine family has proven they run best with long exhaust durations. That is also, true with supercharged engines, in general. Computer analysis showed that the LS7's 230° exhaust duration was ideal for the supercharged LS9 even though it was 51 cubic inches smaller and had a 500 rpm lower rev limit. Such are the benefits of boost.

LS9 valve lift is about .030" less than that of the LS7 because the two engines have different rocker arm ratios, 1.7:1 for LS9 and 1.8:1 for LS7. The exhaust valve timing is four degrees advanced to to reduce supercharger losses and accomplish a 27% overlap reduction in the interest of improving idle quality. The overlap decrease along with the cylinder heads' swirl wings contribute to about an 11% increase in idle quality, compared to the LS7.

Camshaft Profile, Intake Comparison

(All lift figures are valve lift)

| year RPO |

int. lift |

int. dur. at .004 |

int. dur. at .050 |

int. open at .004 |

in. close at .004 |

in. open at .050 |

in. close at .050 |

int. CL |

int. area |

int. area increase |

|---|---|---|---|---|---|---|---|---|---|---|

| MY01 LS6 |

13.34 mm .525 in |

270° |

204° |

9° BTDC |

81° ABDC |

18 ATDC |

42 ABDC |

118° ATDC |

1862.9 mm/deg. |

n/a |

| MY02 LS6 |

14.01 mm .551 in |

267° |

204° |

7° BTDC |

80° ABDC |

19° ATDC |

43 ABDC |

120° ATDC |

1936.9 mm/deg. |

4% |

| MY05 LS2 |

13.34 mm .525 in |

270° |

204° |

9° BTDC |

81° ABDC |

18° ATDC |

42 ABDC |

118° ATDC |

1862.9 mm/deg. |

0 |

| MY06 LS7 |

15.06 mm .593 in |

276° |

210° |

8° BTDC |

88° ABDC |

18° ATDC |

48° ABDC |

122° ATDC |

2166.4 m m/deg. |

16% |

| MY08 LS3 |

14.01 mm .551 in |

267° |

204° |

7° BTDC |

80° ABDC |

19° ATDC |

43 ABDC |

120° ATDC |

1936.9 mm/deg. |

4% |

| MY09 LS9 |

14.27 mm .562 in |

277° |

211° |

8 BTDC |

89 ABDC |

18 ATDC |

49 ABDC |

122 ATDC |

2054.6 mm/deg. |

10% |

Camshaft Profile, Exhaust Comparison

(All lift figures are valve lift)

| year RPO |

exh. lift |

exh. dur. at. .004 |

exh. dur. .050 |

ex. open .004 |

ex. close .004 |

ex. open .050 |

ex. close .050 |

exh. CL |

exh. area |

ex. area change |

|---|---|---|---|---|---|---|---|---|---|---|

| MY01 LS6 |

13.33 mm .525 in |

275° |

211° |

65° BBDC |

30° ATDC |

37 BBDC |

6 BTDC |

114° BTDC |

1914.6 mm/deg. |

n/a |

| MY02 LS6 |

13.91 mm .547 in |

282° |

218° |

69° BBDC |

33° ATDC |

42 BBDC |

4 BTDC |

115° BTDC |

2046.6 mm/deg. |

8% |

| MY05 LS2 |

13.33 mm .525 in |

275° |

211° |

65° BBDC |

30° ATDC |

37 BBDC |

6 BTDC |

114° BTDC |

1914.6 mm/deg. |

0 |

| MY06 LS7 |

14.95 mm .589 in |

296° |

230° |

81° BBDC |

35° ATDC |

53 BBDC |

3 BTDC |

119° BTDC |

2359.4 mm/deg. |

23% |

| MY08 LS3 |

13.33 mm .525 in |

275° |

211° |

66° BBDC |

29° ATDC |

38 BBDC |

7 BTDC |

115° BTDC |

1914.6 mm/deg. |

0 |

| MY09 LS9 |

14.17 mm .558 in |

295° |

230° |

84 BBDC |

31 ATDC |

56 BBDC |

6 BTDC |

123 BTDC |

2238.6 mm/deg. |

17% |

Valve sizes, 2.165-in, intake, and 1.580-in., exhaust, are the same as LS3, however, the LS9 uses titanium intake valves, whereas the LS3's are stainless steel. GM Powertrain went to the ti valve even though the engine's rev limit is the same as that of the LS3 because: 1) the valve head had to be beefed-up to withstand the additional combustion pressure present in a supercharged engine and 2) the LS9 camshaft, by virtue of being just a bit more aggressive, required a slightly lighter valve.

Those needs were impossible to meet with the LS3 intake, even with its hollow stem, so GM upgraded the LS9 to lighter, R54620 titanium intake valves. Like the LS7's ti valves, LS9 units are treated with a chrome-nitride, anti-corrosion/anti-wear coating and have their stems precision-fitted with steel lash caps. The exhaust valves have 422 stainless steel heads and hollow, sodium-filled, SilChrome stems. Like LS3, faces on both valves have 45° angles.

Other LS9 valvetrain parts, including the offset intake rocker arms, carry over from the LS3. See the CAC's LS3 article for more details.

|

|