Ruthless Pursuit of Power: Our In-Depth Look at the 2008 Corvette LS3 Engine - Page 3 of 6

Ruthless Pursuit of Power: 2008 Edition - Page 3 of 6

Our In-Depth Look at the New 2008 Corvette LS3 Engine

|

|

© 2007 by Hib Halverson

No use without permission, All Rights Reserved

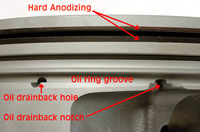

More cutting-edge technology is in the LS3 piston and ring package. The piston is a flattop design, cast with a hypereutectic, aluminum/silicon alloy containing traces of copper and nickel. The compression ratio, 10.7:1, is down slightly from 10.87:1 in '05-'07. This piston is the same as the L92's 10.5:1 unit except for a valve relief the truck piston has for additional piston-to-valve clearance required by the L92's variable cam phasing. When the relief is removed, 0.2 compression is gained but, to get higher than 10.7 requires a domed piston, the cost of which was deemed unnecessary considering LS3 met its performance and efficiency goals at 10.7:1.

Ring grooves are machined with a slight upward tilt which was increased by 0.25° for '08. The top ring's tilt disappears as the ring land flexes under the pressure of combustion such that sealing and oil control are optimized. The other two grooves' tilt enhances the ability of the second ring and the oil ring to scrape oil off the cylinder walls. To further improve oil control, the LS3 piston has four holes drilled in its skirt, just below the oil ring groove downwards into its interior. These holes, two adjacent to the major thrust surface and two adjacent to the minor thrust surface, improve oil drainage from below the oil ring.

Surfaces either side of the top ring groove are hard-anodized. The piston skirts are coated with the antifriction polymer introduced on LS6 for MY02. Interestingly, the pistons are installed with -2 micron (-.00008-in or eight hundred-thousandths of an inch) piston-to-bore "clearance"–a slight interference fit. During break-in, some of the coating wears away, leaving a nominal piston-to-bore clearance. LS3 pistons use new wrist pins having tapered inside diameters, an idea straight from the C5R race program and which reduces pin weight with no loss in strength.

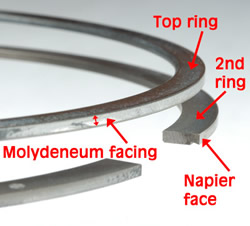

Oil control at high rpm has been a challenge with Gen 3/4 engines. Since 1997, to that end, GM has tried several combinations of crankcase ventilation systems and ring tension. While, for '08, the PCV caries over from LS2; the ring package has, once again, been changed. The top ring is still moly-faced steel and "coin twisted," which means its shape in side view is slightly conical to improve the ring's sealing when under combustion pressure. The second ring remains cast iron with the "Napier" face introduced in MY02 and they both are 1.5-mm. wide with the same tension as before. The oil ring is still three-piece, two rails and an expander, however, to improve oil control, for '08, its tension was increased.

Image: GMPT Communications

Major Cylinder Head Evolution

If there's anything GM Powertrain knows well, it's cylinder heads and air flow. GMPT's "ruthless pursuit of power" has paid-off in four different Vette heads since MY97: the original LS1 head, those for LS2 and LS6, the super-trick LS7 head and, now, the LS3.

Like the block design, the Gen 3 SBV8 head was of interest to Chrysler when it was designing its Hemi. While it has different combustion chamber a second spark plug, a Hemi's head borrows from the LS1 casting.

The high-performance, L92 version debuted in 2007 GMC Yukon XLs and Denalis (380hp) and Cadillac Escalades (403hp) and was the source of the casting used for the LS3 head assembly. It's key improvement over the LS1 and LS2/LS6 heads is revision of the intake and exhaust port shapes, volumes and locations. Those changes were influenced by the '06 Z06. In fact, the L92 head was the "first" LS7 head. Part way through development, when the goal was raised to 500hp, that head was set aside and development began on a second, more aggressive design which eventually went on the C6Z's engine.

Later, when a high-performance, 6.2 was needed for premium SUVs; Powertrain put that first LS7 head back on the front burner and, after more development, it went to production for the L92. Shortly thereafter, when the upgrade program for the base engine in America's Sports Car was initiated, GMPT took the L92 casting, added some parts unique to Corvette's performance envelope and used it on the LS3.

While this new head is not a "clean-sheet-of-paper" design, it is a major evolution in Gen 3/4 cylinder head architecture and its effect on performance is profound. There were a multitude of changes which we'll discuss in detail and, for this part of our GMPT visit, the Design Responsibility Engineer (DRE) for Small-Block Cylinder Heads, Lou Oniga, joined John Rydzewski. A "DRE" is a key person on any project at GM. "The buck stops with the DRE," Oniga told us. "If anything goes wrong with their part, it is their responsibility to make it good–casting, machining, assembly, testing, drawing, dimensioning, validation, or field issues, etc. It is the DRE who is responsible. No one else! Humans sometimes make mistakes. That is why most DRE's you meet are such a strange lot. We always worry–we always are concerned that everything we do is as close to perfect as possible."

|

|